Expertise · Guarantee · Quality

- Filter

- Product Type

- Fabric Roll

- Ready-Made

- For Amazon Seller

- Market

- Construction

- Agriculture & Farming

- Garden & Landscape

- Leisure & Recreation

- Greenhouse

- Architectural

- Mining & Industry

- Water Management

- Advertising Material

- Cargo Control

- Sport Outdoors

- GSM

- <50gsm

- 51-100gsm

- 101-150gsm

- 151-200gsm

- 201-300gsm

- 301-500gsm

- 501-700gsm

- 701-1000gsm

- >1000gsm

- Fabric Type

- Polyester

- Fiberglass

- Polyethylene

- Polypropylene

- Coating

- PE

- PP

- PU

- POE

- PVC

- Silicone

- Aluminum

- No Coating

- Lifespan

- <1 Year

- 1-3Year

- 3-5Year

- 5-10Year

- >10Year

- Waterproof

- Waterproof

- Breathable

- Waterproof & Breathable

- Fire Retardant

- FR

- Non FR

- Brand

- TARPMAX

- MEITEX

- NORDENSHADE

- PLASTUF

- COVERTAC

- TERATUF

- SUNPOLI

- JPLAS

- BEISTAR

- GOLDENTHREAD

Categories

- Industrial Fabrics

- PVC Coated Fabric

- Tarpaulin & Tent Fabric

- Truck Cover Fabric

- Flexible Ventilation Duct Fabric

- PVC Canvas Fabric

- Inflatable Fabric

- Membrane Structure Fabric

- High Speed Door Fabric

- PVC Fence Fabric

- PVC Mesh Fabric

- Double-Wall Dropstitch

- Textilene Vinyl Mesh Fabric

- Transparent Leno Fabric

- Blockout / Blackout Fabric

- Fire Retardant Fabric

- Clear PVC Film

- Printed PVC Fabric

- PVC Tarpaulin Rolls

- Industrial Curtain Fabric

- PE/PP Coated Fabric

- Shade Fabric

- Plastic Net & Mesh

- Woven Fabric

- Non-Woven Fabric

- Composite Fabric

- Plastic Film

- Geosynthetics

- Others

- PVC Coated Fabric

- Fabric-Made Products

- Others

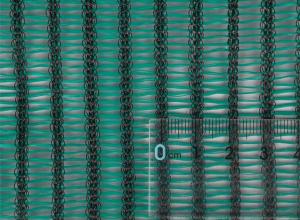

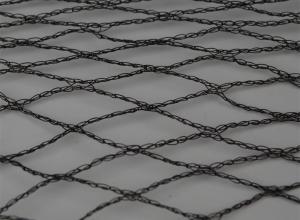

Plastic Net & Mesh

Plastic net and mesh are versatile materials used in a wide range of applications. They are made from high-quality, durable plastic materials and feature a network of interconnected strands or openings. Plastic net and mesh come in different sizes, shapes, and configurations, providing a variety of uses across industries.

14 results

ViewShowcase

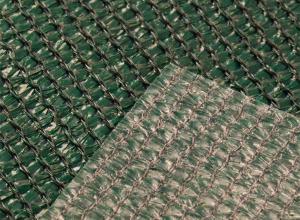

Safety net is made of polyethylene by adding UV stabilizers and anti-oxidants.

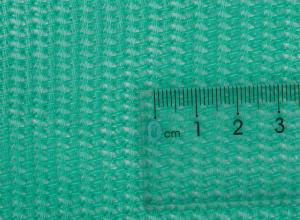

Easiest way to cool any structure. In a greenhouse, shade fabric can significantly lower your summer cooling costs

Sun shades are essential to creating a relaxing outdoor seating area away from the heat and brightness of the sun.

UV-stabilized polyethylene shade nets cut summer sun, while allowing cool air to circulate freely.

Good shading rate and good air permeability can create a bright and comfortable environment space in the greenhouse work.

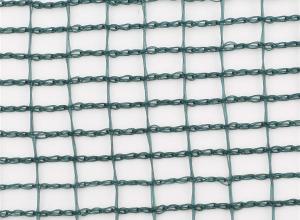

Lightweight, sturdy, easy-to-use square mesh net will help you achieve the best results in your garden.

Aluminum coated polythelene tape yars are knitted for breathable contruction and obtain strength

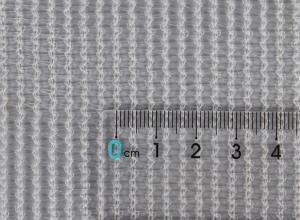

Create a waterproof layer in many situations including carport, vertical blinds and outdoor areas.

Durable and easy to install, protects plants and crops from direct exposure to excessive sunlight.

Agro Shade Net is made of polyethylene (HDPE) material by adding UV stabilizers and anti-oxidants.

Safety net is made of polyethylene by adding UV stabilizers and anti-oxidants.

Has been designed and tested to offer the highest quality insect netting available for Cabbage Root Fly, Carrot Root Fly.

Plastic anti-bird netting is economical and reliable in plant protection against birds.

Types and Features of Plastic Net & Mesh

There are several types of plastic net and mesh available, each offering unique features and benefits. Here are some common types:

Garden Netting: Garden netting is specifically designed for use in horticulture and agriculture. It helps protect plants from pests, birds, and harsh weather conditions, allowing for healthy growth.

Safety Netting: Safety netting is used in construction sites, sports facilities, and other areas where fall protection is required. It provides a barrier to prevent accidents and ensure the safety of workers and individuals.

Fencing and Enclosures: Plastic net and mesh are widely used in fencing and enclosures for residential, commercial, and agricultural purposes. They provide security, boundary definition, and containment for animals, crops, or construction sites.

Packaging and Shipping: Plastic net and mesh are used in packaging and shipping industries to secure and protect various items, such as fruits, vegetables, bottles, or fragile goods. They provide ventilation and prevent damage during transportation.

Filtration and Sieving: Plastic net and mesh with specific opening sizes are utilized in filtration and sieving processes. They allow the passage of desired particles while filtering out unwanted debris or impurities.

Erosion Control: Plastic net and mesh are employed in erosion control applications, such as slope stabilization, sediment control, or shoreline protection. They help prevent soil erosion and maintain ecological balance.

Benefits and Applications of Plastic Net & Mesh

Plastic net and mesh offer numerous benefits and find applications in various industries and settings, including:

Versatility: Plastic net and mesh can be customized to suit specific needs, including size, shape, and strength requirements. They can adapt to different applications, making them highly versatile solutions.

Durability: These materials are designed to withstand harsh environmental conditions, including exposure to UV rays, moisture, and temperature fluctuations. They offer long-lasting performance and require minimal maintenance.

Lightweight and Flexible: Plastic net and mesh are lightweight, making them easy to handle and install. They can be easily cut, shaped, or manipulated to fit specific spaces or requirements.

Cost-Effective: Plastic net and mesh are often more cost-effective than alternative materials, such as metal or wood. They offer a balance between affordability and performance.

Environmental Friendliness: Some plastic net and mesh options are made from recycled or recyclable materials, contributing to sustainable practices and reducing environmental impact.

Installation and Maintenance

Installing and maintaining plastic net and mesh involve the following considerations:

Proper Installation: Follow the manufacturer's guidelines or seek professional assistance to ensure proper installation. This ensures optimal performance and longevity of the net or mesh.

Regular Inspection: Periodically inspect the net or mesh for any damage, such as tears, loose connections, or signs of wear. Prompt repairs or replacements can prevent further issues and ensure continued functionality.

Cleaning and Care: Cleaning plastic net and mesh is typically straightforward. Use mild soap, water, and a soft brush to remove dirt, debris, or residue. Avoid using harsh chemicals or abrasive materials that may cause damage.

Choosing the Right Plastic Net & Mesh

Consider the following factors when selecting plastic net and mesh:

Application-Specific Requirements: Determine the specific needs of your application, such as size, strength, and durability. Choose a net or mesh that can withstand the intended conditions and provide the desired functionality.

Material Quality: Ensure the plastic net or mesh is made from high-quality materials that are suitable for the intended application. Consider factors like UV resistance, tensile strength, and chemical resistance.

Size and Configuration: Select the appropriate size and configuration of the net or mesh based on your specific requirements. Consider factors such as mesh opening size, strand thickness, and overall dimensions.

Supplier Reputation: Choose a reputable supplier or manufacturer known for producing reliable and high-quality plastic net and mesh products. Check customer reviews, certifications, and warranties for assurance.

Plastic net and mesh offer a wide range of applications and benefits across various industries. Their versatility, durability, and cost-effectiveness make them go-to solutions for different needs. When choosing plastic net and mesh, consider the specific requirements of your application and ensure proper installation and maintenance to maximize their functionality and lifespan.

Sign Up to Get Latest Updates

Contact us

Office: No. 6, Cuiling Road, Qingdao, Shandong, China

Office: No. 6, Cuiling Road, Qingdao, Shandong, China Factory: Qingdao · Weihai · Binzhou · Tai'an

Factory: Qingdao · Weihai · Binzhou · Tai'an +86-532-88915029

+86-532-88915029 Send Email to us

Send Email to us